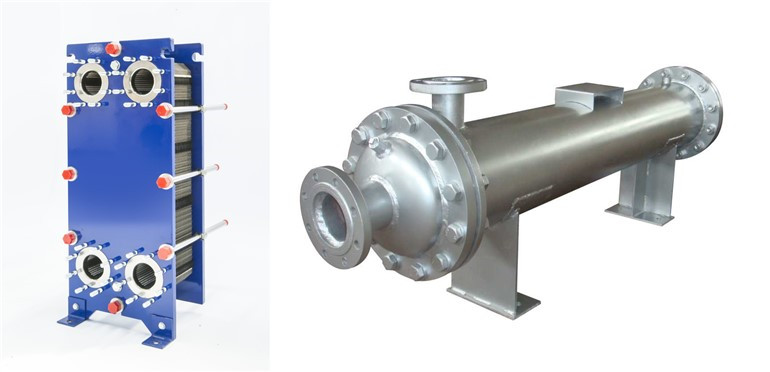

Comparison of plate heat exchanger and shell and tube heat exchanger?

1, Heat transfer efficiency:

The structure of the shell-and-tube heat exchanger is very good in terms of strength, but it is not ideal from the perspective of heat exchange, because the fluid will flow through the bypass in the shell side and not fully participate in the heat exchange.

In the plate heat exchanger, there is no bypass, and the corrugation of the plate can cause the fluid to produce turbulence at a smaller flow rate. Therefore, the plate heat exchanger has a higher heat transfer efficiency.

Under the same heat exchange task, the heat exchange area required by the two is only 1/3-1/4 of the shell-and-tube heat exchanger.

2, Easy to clean:

After removing the compression studs of the plate heat exchanger, the plate bundle can be loosened, or the plates can be removed for mechanical cleaning, which is very convenient for the heat exchange process that requires frequent cleaning of the equipment.

3. Easy to change the heat exchange area:

Since the heat exchange plates are easy to disassemble, only adding or reducing a few plates can achieve the purpose of increasing or reducing the heat exchange area. The heat exchange area of the equipment can be easily increased or decreased, and the increased area of the shell-and-tube heat exchanger needs to be increased a device.

4. Light weight:

Usually the plate thickness of the plate heat exchanger is only 0.5mm, while the thickness of the heat exchange tube of the shell-and-tube heat exchanger is 2.0-2.5mm; in the case of completing the same heat exchange task, the weight is only the shell-and-tube heat exchange About 1/5 of the device.

5. Floor area:

The plate heat exchanger has a compact structure. The heat exchange area per unit volume is 2-5 times that of the shell-and-tube type. Unlike the shell-and-tube type, there is no need to reserve a place for maintenance of the tube bundle. Therefore, the same heat exchange can be achieved. The heater has a smaller footprint.

6, Low heat loss:

Only the shell plate of the heat transfer plate of the plate heat exchanger is exposed to the atmosphere, so the heat dissipation loss can be neglected, and no heat preservation measures are required. The shell-and-tube heat exchanger has a large heat loss and requires a thermal insulation layer.

If you have any plate heat exchanger questions, please contact MC Heat Parts any time!