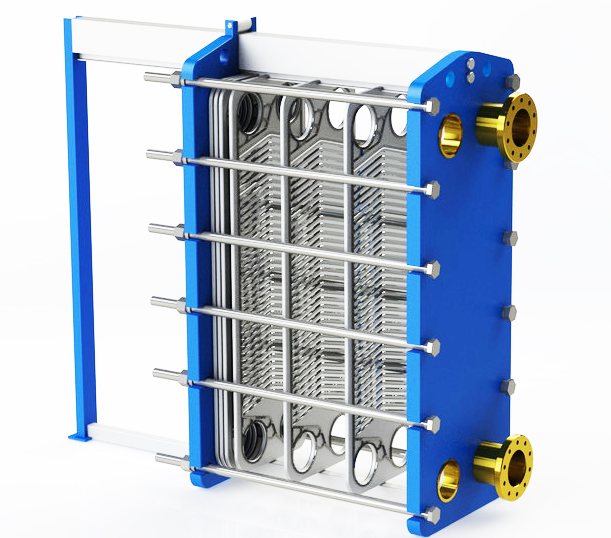

M&C can supply many kinds of plate heat exchanger, Can also be customized according to customer need

1. Carbon steel heat exchanger

Carbon steel refers to iron-carbon alloys with a carbon content of less than 2.11 percent, which is what we call carbon steel. His hardness is high, the quality is high, and the plasticity is low. It is a typical "over-steel is easy to break", it is relatively easy to rust, and its corrosion resistance is general. At present, carbon steel heat exchangers have been gradually replaced.

2. 304-316 stainless steel heat exchanger

Stainless steel heat exchangers are relatively common corrosion-resistant heat exchangers currently on the market. Stainless steel contains a stainless element-chromium, which forms an oxide film on the surface, which is what we often say as a passivation film. The passivation film is not easy to dissolve in common acid and alkali salts and other media. Generally, the cl ion content does not exceed 400mg / l and the temperature is within 130. 316 stainless steel chlorine can be used. Ion content does not exceed 100mg / l, and 304 stainless steel can be used within a temperature of 120.

3. Titanium heat exchanger

Titanium heat exchangers are heat exchangers with extremely high corrosion resistance. Titanium heat exchangers use high-quality titanium plates. In terms of physical properties, titanium has the advantages of light weight and superior mechanical properties. In terms of chemical properties, titanium has good stability, and has good corrosion resistance in many industrial solutions. Generally speaking, TAI can be used when the chloride ion concentration is 5000mg / l to 7000mg / l.